Been awhile since I’ve posted, blah blah blah. I’ve been busy in the interim; I’ve lived in 5 places since then, taken trips, etc. Some details on what I’ve been doing in the interim coming soon. This post, however, is about something more amusing.

A few months ago, I found a video of an awesome “Japanese Ice Mold” online. The idea is simple:

- People like drinks cold.

- Ice makes things cold.

- Ice melts.

- People don’t like water in their drinks.

- To prevent melting, you should have the maximum volume (making things cold) with the minimum surface area (melting).

- The shape that does this is called a sphere.

- It’s hard to take water and make spheres that don’t have ugly seams in them.

- Through the magic of thermodynamics, you can use a metal to melt some parts of a block of ice, while freezing the resulting water, and get a beautiful sphere.

At this last bit, the physics student in me is screaming “but that makes no sense!” Admittedly, I didn’t do very well in physics, so it wasn’t screaming very loudly. I really thought that my brother, Quinlan (who’s a liquor snob and has more parties than I) needed this for a party. However, the fact that it costs freaking $1400 put it well out of my range; Quinlan didn’t need it that badly. As I looked at it, though, I realized that it wasn’t a hard concept: just get a big block of aluminum with a spherical hole, heat it, and you’re done. Surely, I could make this. If only I was a member of a hackerspace with milling tools… but wait! I am!

When I brought the concept to my local hackerspace, Sector67, however, Chris Meyer (the lord-high poobah and resident expert) was entirely sure it wouldn’t work, due to his actually knowing real physics. The video, however, was persuasive:

So, with some trepidation (due entirely to how bad I am with large machinery), Chris said I should try it out. Sector67 has many friends, and one of those friends, Isthmus Engineering, was kind enough to give us a scrap piece of 1.5” thick aluminum billet, which had enough area left on it to take two squarish chunks out, each a bit longer than 3” on a side. Chris kindly taught me to use the metal bandsaw to cut them, then the manual mill to make the squarish chunks pretty square and approximately the right size. Then he introduced me to the CNC mill, which I taught to make a sphere in SolidWorks.

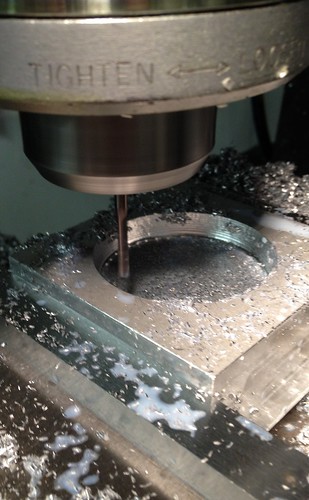

Then the fun started. I should preface this by noting that on the day I came in, I was four days out from my first final in law school (oh yeah, I’m in law school at the University of Wisconsin School of Law). So I maybe should have been studying. But this was more fun. Anyway, the mill started going.

And going.

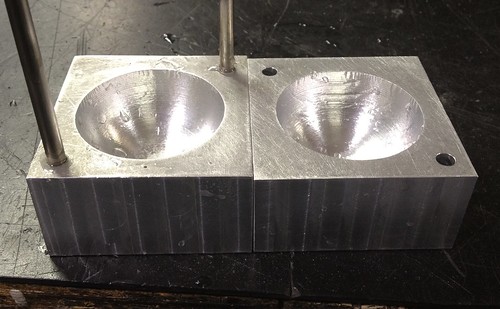

Finally, after ~4 hours of mill work, we had half a mold! We heated it and applied it to some ice we had laying in the back of the freezer, and lo, there was a hemisphere:

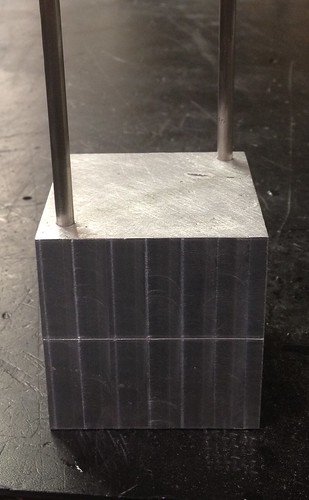

It also produced a whole lot of shavings, which Chris informs me is the way you can convince other people there was effort involved in a mill job:

I went home to study, and came back a few days later; after just one very minor disaster, there was a mold:

So then, now to test. Using rails from some old printer rollers (yes, seriously, and yes, there’s a huge box of these things at Sector67), we put it together:

All you have to do, then, is heat it up (under running hot water is sufficient), put a block of ice in, and let the top half fall:

Voila, you have a perfect seamless sphere:

Add vodka (or your liquor of choice), and serve:

Life, as they say, is good. And Quinlan even liked it, which helps.

This entire project wouldn’t have been possible without both the kind assistance of Isthmus Engineering (they do neat stuff, and support poor hackerspaces like Sector67) and the entire Sector67 crew, especially Chris, who both knows how to use everything safely, and is willing to teach people with less mechanical skill than an average cucumber like me! Thanks to everyone at Sector67 for being patient with my ~12 hours of loud mill time, too, especially when they were shooting a documentary in the next room.

Update: In response to a user request in the comments, I’ve uploaded the files for this to Thingiverse. Enjoy!

Update 30 January 2012: Thanks to both Make Magazine’s Blog and Hack A Day for covering this!